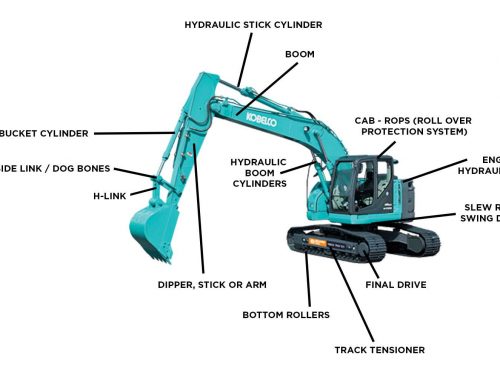

Wheel loader is mainly composed of five major parts: power unit (engine), chassis, working device, hydraulic system and electrical system.

1- Diesel engine system 2-Drive system 3- Roll over and falling object protection device 4-Pilothouse 5- Air conditioning system 6-Steering system 7- Hydraulic system 8-Frame 9- Working device 10- Braking system 11- Electrical Instrument System 12-Covering parts

Figure 1-3 shows the overall structure of the most representative ZL50C wheel loader in China at present. It consists of diesel engine system, transmission system, anti-rollover and falling object protection device, cab, air conditioning system, steering system, hydraulic system, frame, working device, braking system, electrical instrumentation system, covering parts and manipulation system.

(1) Power unit

The power unit used in wheel loaders is mainly diesel engine. It is arranged at the rear, in the middle of the cab, so that the center of gravity of the whole machine is more reasonably positioned and the driver has a better view, which is conducive to improving the quality of operation and productivity. The power is transferred from the diesel engine to the torque converter, and then through the universal coupling, it is transferred to the gearbox. Through the transmission, the power is transferred to the front and rear axles to drive the wheels respectively.

(2) Chassis

The chassis of wheel loader includes four major parts: transmission system, travel system, steering system and braking system.

- Transmission system Loading ah and the transmission system are mechanical, hydro-mechanical, hydraulic and electric transmission four, small loaders are mostly mechanical, due to the poor adaptability of the operating conditions, has been eliminated; large and medium-sized loaders are widely used hydro-mechanical; medium-sized loaders are mostly hydraulic; large loaders are mostly electric transmission type.

- Walking system is one of the important components of wheel loader chassis, mainly consisting of frame, axle and wheels, etc. It makes the loader assemblies and parts connected into a whole; supports all the weight, absorbs vibration, moderates impact, and transmits various forces and moments. The frame is divided into integral type and folded type. Wheel loaders are mostly articulated (also known as bending type) frame.

- Steering system The steering system of wheel loader has a variety of mechanical steering, hydraulic power-assisted steering and full hydraulic steering. At present, most of the wheel loaders use hydraulic power-assisted type and fully hydraulic type to realize the form and operation of often changing its driving direction or keeping a straight line.

Braking system It is an important part of wheel loader, usually with travel brake system, emergency and parking brake system, which is used to slow down or stop the moving loader to improve the operation speed and operation productivity of the loader.

(3) Working device

The working device of wheel loader consists of oil pump, moving arm, bucket, lever system, moving arm cylinder and bucket cylinder, etc. The power of the oil pump comes from the engine. The moving arm is hinged on the front frame, and the lifting of the moving arm and the reversing of the bucket are realized by the movement of the corresponding hydraulic cylinder.

(4) Hydraulic system

The hydraulic system of wheel loader varies with different power system buckets. For hydro-mechanical transmission of the loader in addition to the work device and steering using hydraulic transmission, its power shift transmission shift manipulation system also uses hydraulic control; usually composed of oil pump, oil cylinder, reversing valve, diverter valve, oil and oil tank. The power is transmitted to the working device through the oil and fluid to realize the purpose of loading and unloading bulk materials, cleaning the site and short-distance material handling.

(5) Electrical system

The electrical system of wheel loader is to start the generator, as well as to supply power to lighting and signal equipment, instrumentation and detection equipment, electric control equipment and other auxiliary equipment, in order to ensure the safety of the loader’s driving and operation. It includes power supply system, starting system, lighting and signal system, monitoring and display system and auxiliary system, etc.

Leave A Comment